2024 / 03 / 26

Projection welding is characterized by joining a predetermined weld point with the parent material. These points are also referred to as projections or embossments. Projection welding machines apply the current and weld forces on these predetermined weld points, unlike spot welding where the weld is determined by the size or shape of the electrode. These Projections can be produced by embossing on sheet metal, machining or cold forging on a solid piece and press punch on the edge of a piece. Projection welding has a wider range of applications than spot welding; from welding nuts and bolts to sheet components to huge bearings and crossbars that form grating panels. Projection welding machines are usually larger than spot welders and offer more weld power and weld force.

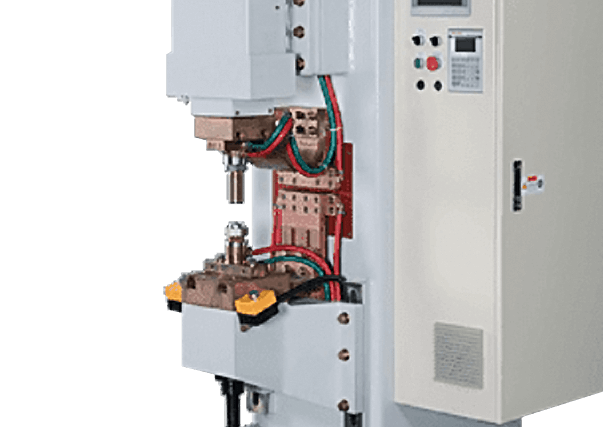

Stationary Projection Welding Machine (Pneumatic)

The lower knee is probably the most obvious characteristic of a projection-style welder. In contrast to a spot welder, a projection welder's lower knee is box-constructed for mounting tools and fixturing. T-slot platens are commonly attached to projection welders to allow for rapid tool changeover, similar to how vertical machines have t-slots for quick tool change.

When weld arms are used these are usually squared to reduce the degrees of freedom while increasing setup time and repeatability. More simple models don’t have any platens if tool change is not required. As mentioned, this type of welding machine uses weld projections on the component to create multiple high-quality welds in one go, hence the name ‘projection welder’. Welding many welds at once often require a greater weld force and therefore a stronger frame compared to a simple spot weld.

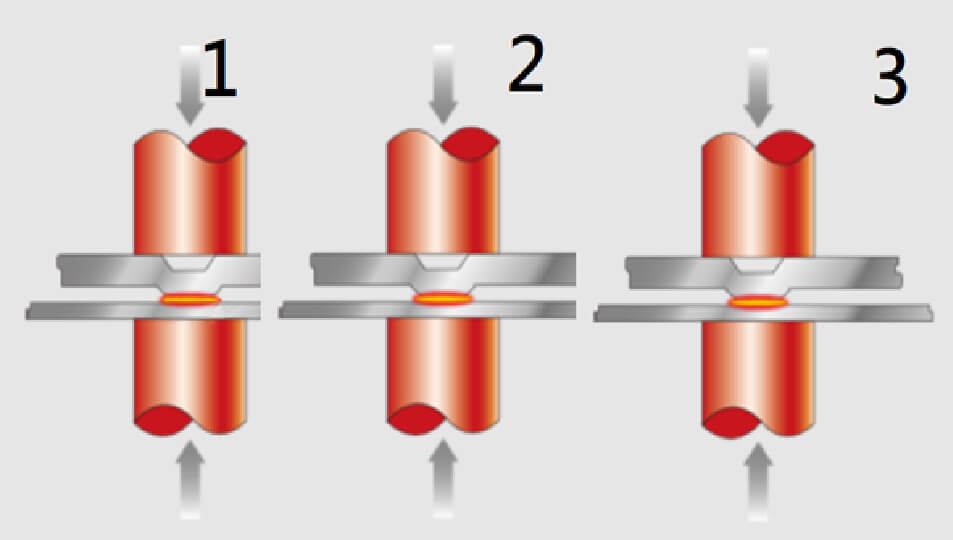

The most crucial components during the projection welding process are the two flat electrodes that are the conductors of heat and electricity. Between the electrodes, the two pieces of metal to be welded together are placed. Two huge, upper, and lower plateaus apply a large pressure force to the electrodes that release the current onto the workpieces. Heat is generated as the current flows due to the internal resistance of the metal workpiece. Only the two workpieces or the sheets touch the projections points. Therefore, the heat produced by the resistance focuses projections on the workpiece. With projection welding, one or more points at the same time can be welded.

Projection Welding Process

The projections absorb and disperse heat which allows projection welders to achieve very unique forms and strong welds. Even contact and pressure between the fastener's projections and the base metal practically eliminates excessive electrode pressure. In most cases, several tiny projections are generated on the surface of the welded pieces. These projections can be spherical, elongated ridges, or circular or even weld nut corners. A contact point is formed by two wires held together at 90 degrees.

Projection Welding Electrodes Close-up

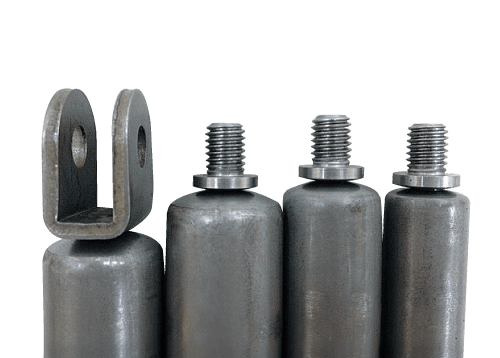

We can distinguish two main types when it comes to projection welding: embossed and solid projection welding. Embossed projections are created directly on the source material and they concentrate the current flow on these projections. These are mostly used for sheet-to-sheet welding. Creating multiple projections allows simultaneous welding of multiple weld spots. Solid projection welding on the other hand uses existing projections on the component. Good examples are welding nuts and bolts on plates or brake drums.

There are quite a few advantages to using projection welding machines. Firstly, they require a lower welding pressure and a relatively low current source. And as less current travels through the electrodes, they usually can be used for a longer time. Unlike spot welding, there are no thickness restrictions on the metals to be welded and you can create multiple spots in one process. You can also expect very clean weld junctions as there are no filler metals involved. Therefore, a projection welder is especially useful for welding joints in difficult-to-reach areas. Overall, projection welding ensures a better weld look and homogeneity than spot welding.

But of course, there are also some drawbacks. You need to keep in mind that projection welding can be a relatively sophisticated and time-consuming procedure that requires trained individuals to form projections of more intricate shapes, such as spherical projections. Also, there is a certain limitation to the workpieces that can be processed, for example very thin parts are not suitable for projection welding machines. When it comes to the materials, certain brasses and coppers are a no-go for projection welding.

Projection Welding is one of the most used types of resistance welding as it delivers high-quality, strong welds very fast. The range of applications is huge. It is an excellent process for attaching metal components with embossments. It's widely used in the electrical, automotive, and construction industries.

Projection Welding Machines are appropriate for customers that want high machine consistency, a lower connected load, day-to-day power savings, and good aesthetics after welding without marks. The majority of the time, projection welding is employed in mass production. It has numerous applications: One typical application is nut and bolt welding of hex nuts, square nuts, round nuts, tube nuts, and more. But it is also very common in the production of sheet metal components for automobiles and hot stamping of CD welding. This welding technique is also utilized for fan covers and hollow metal doors, compressor parts and semiconductors, industrial tanks, and others.

Projection Welded Components

Dahching projection welding machines all deliver flawless circular, arcuate and elongated projections on all kinds of components and materials. Our machines benefit from decades of experience, expertise, and advanced craftsmanship. Each model regardless of the series has a highly rigid structure and massive tables with an easy and reliable welding fixture system. Besides our conventional stationary projection welder, we can also create automation solutions that meet your very specific requirements.

Just click on the machine type you are

most interested in to learn more about it.

You can also check out our Flash Butt Welding Machines and Spot Welding Machines.

我們能提供什麼幫助?

如果您有任何業務諮詢或產品問題,

請隨時與我們聯繫。