Resistance Spot Welder, Projection Welder, Seam Welder, Flash Butt

Welders, Three Phase Welders and Capacitor Discharge Welders

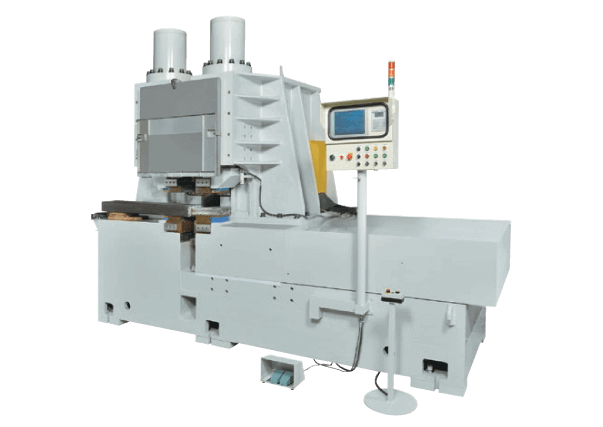

![]() Flash Butt Weld / Butt Weld is a resistance welding that does not require overlap of weld material. It is commonly used to join same or different cross section in tube, bar, rod, sheet or plates. Butt weld is also called Upset weld. Heat for welding is the resistance to electric current created through contacts between the moveable part and the fixed part. As the weld part touches, the material starts to flash and sparks (metal loses) from the weld area. The flashing process heat up the cross section of the weld part, then comes the butt weld (Upset) process. Upset process is to accelerate the movable part towards the fixed part with higher current. Rapid speed and continuous pressure will weld two pieces together. Check out our flash butt welding machine and butt welding machine below.

Flash Butt Weld / Butt Weld is a resistance welding that does not require overlap of weld material. It is commonly used to join same or different cross section in tube, bar, rod, sheet or plates. Butt weld is also called Upset weld. Heat for welding is the resistance to electric current created through contacts between the moveable part and the fixed part. As the weld part touches, the material starts to flash and sparks (metal loses) from the weld area. The flashing process heat up the cross section of the weld part, then comes the butt weld (Upset) process. Upset process is to accelerate the movable part towards the fixed part with higher current. Rapid speed and continuous pressure will weld two pieces together. Check out our flash butt welding machine and butt welding machine below.

What is a Resistance Flash Butt Welding?

Flash Butt Welding is a resistance welding process involves joining two materials without gas or filler material. Two welding materials are clamped on the machine platen, one on the movable platen and the other on the fixed platen. The flashing stage of the flash butt welding process is to apply voltage while movable platen advances towards the fixed platen. The melting and expulsion of the material on the faying surface of the two materials is the flash welding process. The Flash welding terminates at the start of the butt welding process.

What is a Butt Welding machine?

A Butt Welding Machine has similar mechanical appearance as a Flash Butt Welding Machine but are typically smaller than a Flash Butt Welding Machine in terms of capacity, welding force and machine dimension. A butt welding machine has a movable jaw (platen) and a fixed jaw (platen) that clamps and joins two materials together at an accelerated speed with sufficient force and heat. Butt Welding is also referred to as a Upset Welding. Butt Welding Machines are, by its name, does not have the flash welding process.

What is an upset welding?

A Upset welding is similar to a butt welding.

What are the typical applications and materials that can be welded on a Flash Butt Welding Machine?

Most ferrous alloys can be welded, such as carbon steels, low alloy steels, aluminium alloys, stainless steel and nickel alloys. Two materials do not necessarily to be of the same material; dissimilar metals such as Aluminium to steel can also be Flash Butt Welded.

Application-wise, ferrous bars such as flat bars, rectangular bars, H-section, round bars and rebars. Cylindrical-shaped items include engine rings, gasket rings, hoist rings, motorcycle rims, automobile rims, scooter rims, bicycle rims, flanges, etc. Railway welding is also another typical flash butt welding application.

What material or applications can a Butt Welding Machine weld?

Most ferrous alloys can be welded, such as carbon steels, low alloy steels, aluminium alloys, stainless steel and nickel alloys. Sheets, bars, rings with smaller wire diameters. Butt Welding Machine is a good pick for welding tubes with thin wall thickness.

What is the welding sequence in a Flash Butt Welding Machine?

Most common Flash Butt Welding machines or Butt Welding machines are operated automatically with the following procedures.

List out the process variables in a Butt-welding process.

The weld parameters variables include Butt Welding Speed, Butt Welding Pressure or Force, Butt Welding Current, and Butt Welding Distance. Changes in any of the variables may result in different weld strengths.

How to develop the welding parameter for a particular Flash Butt Welding application?

How to develop the welding parameter for a particular Flash Butt Welding application? Ideally, a weld parameter with a similar cross-section can be used as a reference. The weld parameters are primarily developed through trial and error. You may contact Dahching Electric Industrial Co., Ltd for assistance and support.

How can we help?

If you have any business inquiries or product questions,

please feel free to contact us.