2022 / 03 / 29

Flash butt welding is a type of electrical resistance welding used to join components in which the energy is transferred by the resistance heat created by the parts themselves. The components are positioned end to end throughout the whole joint region. A range of section sizes and sophisticated shapes can be combined ( examples are bicycle wheel rims and railway rails, see below). While a flashing voltage is applied, the connecting components are held and gently pushed together. Although the procedure can be performed by hand, the majority of welding machines are mechanical or semi-automatic. Dahching has a wide range of butt welding and flash butt welding machines for its customers. Read on to find out more about these two types of welding machines.

A butt weld is also known as an upset weld. The resistance to electric current caused by contacts between the mobile and fixed parts is referred to as heat for welding. The material begins to flash and spark (metal losses) from the weld location when the weld portion meets. The flashing process warms up the weld part's cross-section, followed by the butt weld (upset) process. The Upsetting process uses a greater current to accelerate the moveable element towards the fixed part. Welding two components together requires high speed and constant pressure.

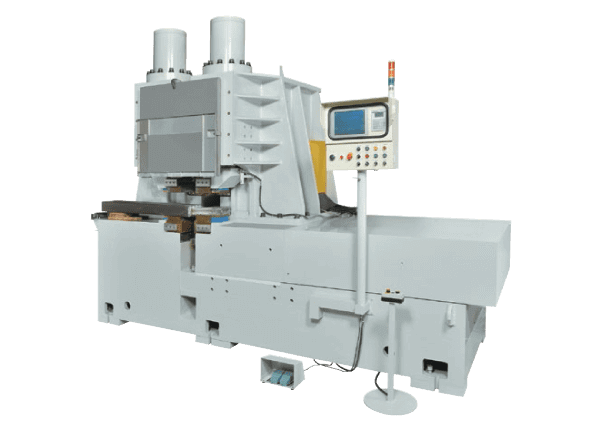

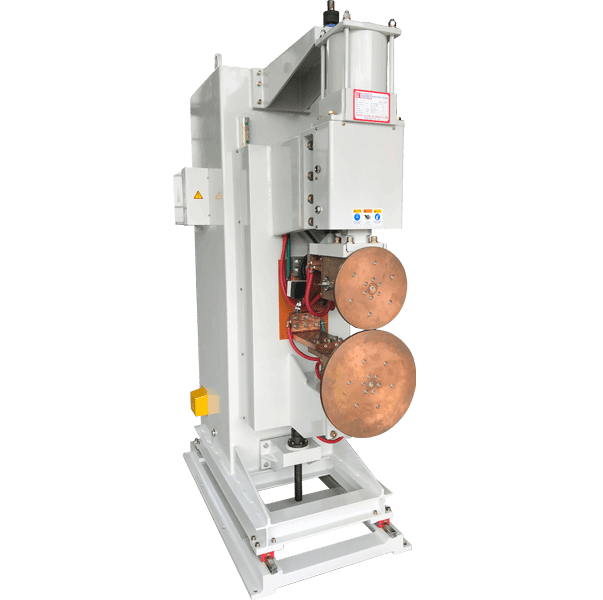

Flash Butt Welder for aluminum and metal alloy

Resistance welding procedures that cause coalescence throughout the whole region of two abutting surfaces at the same time are known as flash welding and butt welding. Butt welding is one of the classic resistance welding processes used for metalworking purposes. Although flash butt welding and butt welding equipment look very similar, there are some important differences in terms of resistance and pressure application. What both approaches have in common, is that the heat source for the actual welding process is the resistance to the electric current of the two opposing surfaces.

Traditional butt welding brings the two workpieces together under high pressure as a first step. The contact area is then heated sufficiently to allow the applied pressure to bind the components together. Therefore, we can categorize butt welding as a single-stage process that makes use of current and pressure. Both are applied during the whole weld cycle until the connection becomes formable. The pressure emitted from a cylinder overcomes the softened zone, which in turn leads to a forging effect and a connected area. There is no change in current or pressure during the cycle and the upset at the weld joint is very smooth and symmetrical without any visible jagged metal extrusion.

Today, new AC butt welding machines can connect small-diameter wires and rods. Examples of such applications are coils for continuous line operations, band saw blade manufacture and wireframes.

Hollow Profile Tube and Bar Butt

Welder

Now, let us take a closer look at the different techniques.

When the wheel rotates along the workpiece in this method of welding, current pulses are produced. The energy to connect components in flash butt welding is mostly produced by resistive heat from the pieces themselves. A current is applied to the pieces of metal to be welded after they have been separated. The metal then starts to melt because there is resistance and a so-called arc between the two workpieces. The arc's presence is defined as the 'flash time.' The molten metal parts that will be connected are forced together under great pressure, forcing the ends to join. There is no requirement for filler metals. An electronic control system is intended to offer a reliable welding process based on pre-programmed parameters.

Flash butt welding machines employ a clamping mechanism consisting of two horizontally placed cylinders that grip the rails with high force to prevent slippage and upsetting during welding. The welding head has a pulling force of 100 tons and more. It automates the whole welding cycle, from alignment to flash removal. Advanced flash butt welding equipment can weld rails with cross-sections up to 15,000mm2 and may be employed on or off track.

This flashing gradually adds warmth and a softened zone at the component ends, removing oxides and impurities from the contact. A forging force is given to the pieces to cement the connection after a defined 'burn-off' length of the parent material. This results in a forge butt weld with no molten metal left in the junction.

Because there are no gaps between the sections, the rail produced is noticeably smoother than mechanically linked rail. Preheat, pre-flash, steady flash, boost, upset, forging, and flash material removal are all part of the flash butt welding process. The welded segment has the same qualities as the remainder of the rail due to the lack of joints. This reduces unequal wear and tear on the rail, as well as inspection and maintenance costs and time.

The computerized control system ensures a consistent welding process and produces high-quality welding connections. The welding head is built to deliver the best quality and tolerances for rail welding in-track and stationary circumstances. Flash butt welding is used for long welded rails as well as to convert short rails or to continuously welded rails. Therefore it is a very versatile process. There are flash butt welding machines that are mobile, to accommodate for flexible manufacture on any job site by road or rail, which increases the efficiency of railroad manufacturing.

Railroad manufacturing is the most traditional use for flash butt welding procedures. The rails are forced together under tremendous pressure during the succeeding upset stroke, forcing the ends to coalesce. The upset metal is removed immediately following the upset stroke. This flash butt welding method is extremely precise without any filler metal. The area affected by the heat is relatively small and allows for a uniform hardening with a very smooth metallic structure as a result.

Butt welding was later powered by a three-phase DC power source. A three-phase DC power supply on a welding machine delivers balanced line demand, lower primary current, and more equal heating of the weld region. Inductive losses are reduced, allowing for greater flexibility in machine design. The three-phase DC butt weld has successfully welded larger cross-sections of ferrous and nonferrous material.

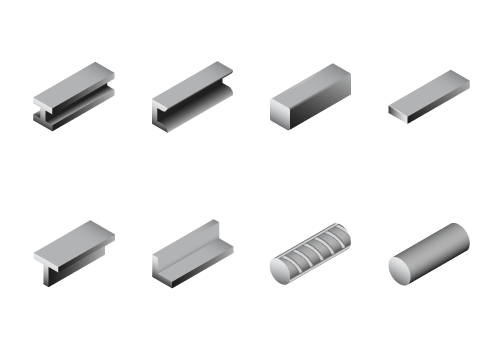

Flash Butt Welded Shapes

Bicycle Rims

As a result, the flash butt welding method is not restricted to train applications. Because technology advances so quickly, the applications for flash butt welding (and also standard butt welding) change all the time. Advanced controls, AC and DC power sources, hydraulic development, and servo valves have all contributed to the enhanced process, expanding the applications that may be accomplished.

As a Dahching customer, you will benefit from our flash butt welding expertise, no matter which type of butt welding machine you are looking for. Our machines offer a variety of automation features, such as flexible clamping. If you are looking for a total solution we can also assist you with planning a whole welding equipment production line to create the perfect combination of robotic technology, seam welding machines including the gun, fixtures, rollers, etc. Each customer gets the individual solution they deserve. As a starting point, first choose the type of (flash) butt welding machine most suitable for your application:

Just click on the machine type you are

most interested in to learn more about it.

If you are more interested in Spot Welding

Machines click here

How can we help?

If you have any business inquiries or product questions,

please feel free to contact us.